High Temp A335 Alloy Pipe P22 T22 & K21590 Wear Resistant Precision Size Boiler Alloy Steel Pipe

ASTM A335 Series Seamless Alloy Steel Pipes & Tubes

As critical pressure-bearing components for industrial thermal engineering, the A335 series seamless alloy steel pipes are manufactured strictly in compliance with the ASTM A335 standard. Covering 16 core material grades, they can be accurately selected based on different temperature and pressure working conditions. The following is a comparison of key specifications for commonly used materials:

Material Grade | Executive Standard | Max Service Temp (℃) | Min Tensile Strength (MPa) | Common Size Range (OD×Wall Thickness) | Core Alloy Composition |

P5/T5 | ASTM A335 | 593 | 415 | 13.7mm-610mm × 2.11mm-50.8mm | Cr5Mo |

K41545 | ASTM A335 | 620 | 485 | 13.7mm-610mm × 2.11mm-50.8mm | Cr5MoV |

P9/T9 | ASTM A335 | 649 | 485 | 13.7mm-762mm × 2.11mm-60mm | Cr9Mo |

K90941 | ASTM A335 | 677 | 515 | 13.7mm-762mm × 2.11mm-60mm | Cr9Mo1 |

P22/T22 | ASTM A335 | 593 | 415 | 13.7mm-1219mm × 2.11mm-80mm | Cr2.25Mo |

P91/T91 | ASTM A335 | 650 | 585 | 13.7mm-1219mm × 2.11mm-80mm | Cr9Mo1VNb |

P92/T92 | ASTM A335 | 675 | 620 | 13.7mm-1219mm × 2.11mm-80mm | Cr9W2MoVNb |

K92460 | ASTM A335 | 690 | 650 | 13.7mm-1219mm × 2.11mm-80mm | Cr9W2MoVNbN |

The A335 series adopts a two-step seamless forming process—hot-rolled piercing + cold-drawing precision rolling—to ensure the integrity of the pipe’s internal structure and avoid defects such as welding seams (a common weakness in welded pipes). During production, each batch of pipes undergoes strict dimensional control: the ovality of the outer diameter is ≤ 0.5% of the nominal diameter, and the surface finish of the inner wall reaches Ra ≤ 6.3μm, which minimizes turbulence loss when fluids (such as steam or heat transfer oil) flow through.

In terms of material coverage, the series is designed to meet diverse industrial needs: low-chromium grades (e.g., P5/T5, P22/T22) are cost-effective options for medium-temperature (300℃-593℃) and medium-pressure scenarios, such as conventional thermal power boiler water walls; medium-chromium grades (e.g., P9/T9, K90941) excel in high-temperature sulfur-containing environments, making them ideal for petrochemical hydrogenation reactors; high-chromium grades (e.g., P91/T91, P92/T92) are equipped with trace alloying elements (V, Nb, W), forming a stable martensitic structure that maintains mechanical strength even at 650℃-690℃, suitable for ultra-supercritical thermal power units and new energy solar thermal power generation molten salt pipelines.

All finished products must pass 100% quality inspections: hydrostatic testing (test pressure ≥ 1.5 times the design pressure) to verify pressure resistance, eddy current testing to detect surface defects, and ultrasonic testing to check internal cracks or inclusions. A full set of test reports (including material certificates, dimensional inspection records, and non-destructive testing reports) will be provided to customers along with the goods.

3. Core Performance Advantages: Adapted to Harsh Industrial Conditions

The competitiveness of the A335 series lies in its targeted solutions to three major industrial pain points: high temperature, high pressure, and strong corrosion.

• Wide-Range High-Temperature Stability: Different grades cover a temperature range of 593℃-690℃. For example, P92/T92 can operate continuously at 675℃ for more than 100,000 hours without significant oxidation peeling; P22/T22, with its balanced Cr-Mo ratio, has excellent thermal fatigue resistance, making it suitable for equipment that starts and stops frequently (e.g., waste heat boilers in steel plants).

• High-Pressure Bearing Capacity: The seamless structure and uniform wall thickness enable the pipes to withstand long-term working pressures up to 30MPa (for P91/T91 grade). In actual applications, this means the pipes can replace heavier carbon steel pipes under the same pressure, reducing the overall weight of industrial equipment by 20%-30%.

• Multi-Medium Corrosion Resistance: For sulfur-containing flue gas or steam mixed environments, Cr5Mo-based grades (P5/T5, K41545) inhibit sulfide stress corrosion; in petrochemical organic acid and high-temperature oil slurry transportation, Cr9Mo-based grades (P9/T9, K90941) resist hydrogen embrittlement and intergranular corrosion; high-end grades like K92460, with added nitrogen, even adapt to molten salt (sodium nitrate-potassium nitrate mixture) corrosion in new energy projects.

Based on its material diversity and performance adaptability, the A335 series has been widely used in four core fields:

• Power Industry: As "blood vessels" of thermal power and nuclear power boilers, it is used for superheater tubes (P91/T92), reheater tubes (P22/T22), and economizer tubes (P5/T5); in new energy, it serves as molten salt transport pipes (K92460) for solar thermal power plants and heat exchanger tubes (P9/T9) for biomass power generation.

• Petrochemical Industry: Applied in hydrogenation reactors (K90941), catalytic cracking unit risers (P9/T9), and high-temperature oil pipelines (P22/T22), resisting corrosion from hydrogen, sulfur, and heavy oil components.

• Chemical Industry: Used for heat exchanger (P5/T5) in ethylene cracking furnaces, pressure vessel connecting pipes (P91/T91) in ammonia synthesis plants, and acid-resistant pipelines (K41545) in sulfuric acid production.

• Marine Engineering: Medium-chromium grades (P9/T9) are used for offshore platform steam boilers, with excellent resistance to humid marine atmospheric corrosion and alternating temperature stress.

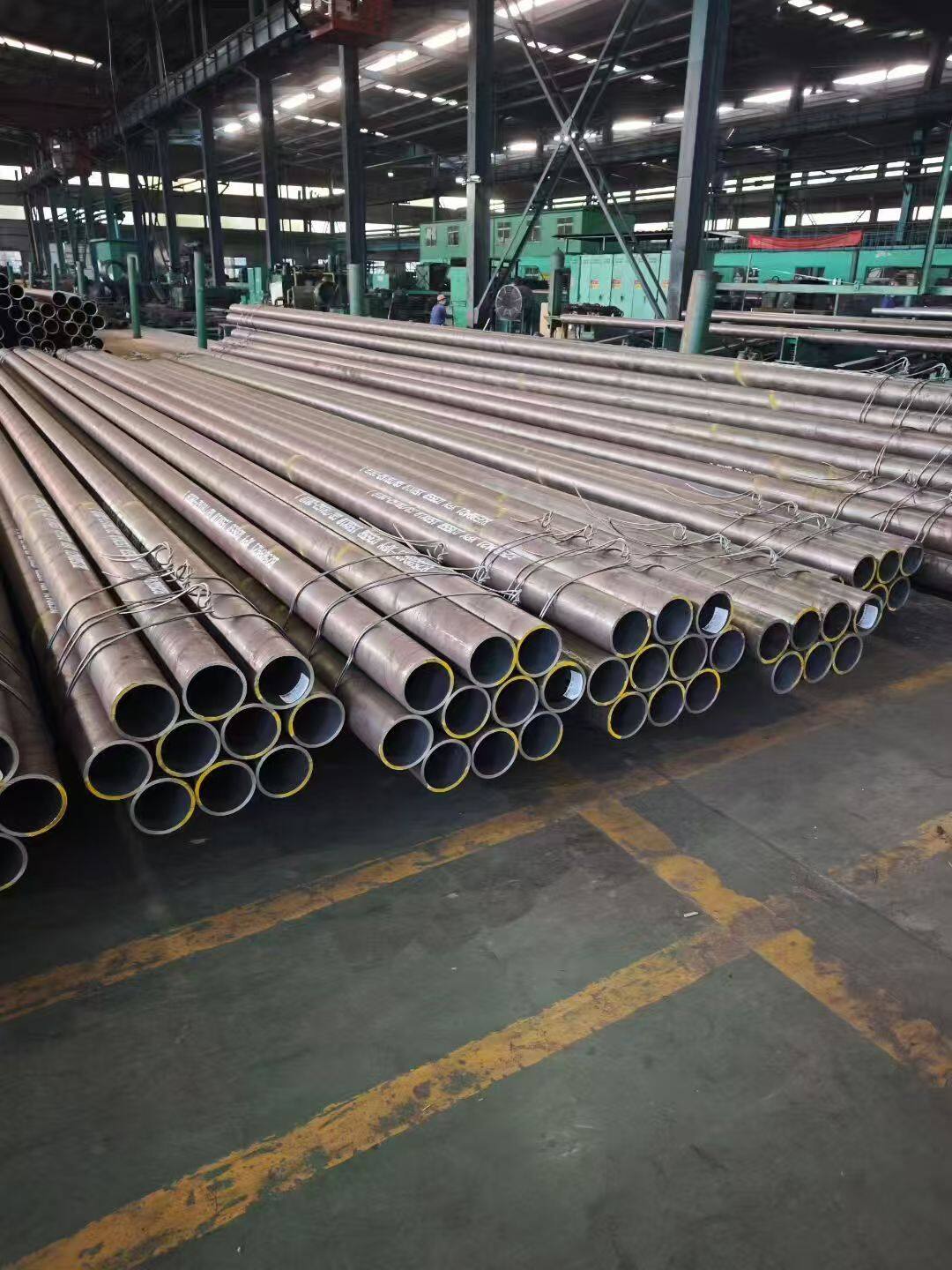

5. About Our Factory: Professional Manufacturer of Industrial Alloy Pipes

We are a leading manufacturer specializing in ASTM A335 series seamless alloy steel pipes, with a production base covering 20,000 square meters and an annual output of 50,000 tons. Our core strengths include:

• Advanced Production Equipment: Equipped with 3 sets of hot-rolled piercing units, 5 cold-drawing precision rolling lines, and a fully automated heat treatment furnace, ensuring stable product consistency.

• Strict Quality Certification: We have obtained ISO 9001 quality management system certification, ASTM material certification, and ASME BPVC Section IX welding qualification, meeting the standards of European, American, and Southeast Asian markets.

• Customized Service Capability: We can produce pipes with special specifications (e.g., ultra-thick walls ≥ 80mm, small diameters ≤ 10mm) and customized heat treatment processes according to customer drawings; the minimum order quantity (MOQ) for standard grades is 1 ton, and the delivery cycle is 7-15 working days.

• After-Sales Support: We provide free material selection consultation (based on customer working conditions), on-site installation guidance, and a 12-month quality warranty. Our technical team responds to customer inquiries within 24 hours.

Send Inquiry to This Supplier

You May Also Like

-

A335 Heat Exchanger Tubes P11 T11 & P12 T12 Thermal Stable Corrosion Resistant Commercial Heat Exchanger TubesNegotiableMOQ: 1 Ton

-

A335 Alloy Steel Pipe K11597 & K11562 High Temp Resistant Uniform Thickness Industrial Alloy PipeNegotiableMOQ: 1 Ton

-

Pressure Resistant A335 Seamless Pipe P22 T22 & P36 T36 Smooth Inner Wall Mechanical Seamless Steel PipeNegotiableMOQ: 1 Ton

-

A335 Boiler Pipe K21590 & K21001 Corrosion Resistant High Temp Tolerant Thermal Power Boiler PipeNegotiableMOQ: 1 Ton

-

A335 Superheater Tubes P91 T91 & P92 T92 Precision Dimension Thermal Stable Power Plant Superheater TubesNegotiableMOQ: 1 Ton

-

A335 Alloy Steel Tube K91560 & K92460 Wear Resistant Smooth Surface Industrial Alloy Steel TubeNegotiableMOQ: 1 Ton

-

A335 Seamless Steel Pipe P5 T5 K90941 High Temp Resistant Pressure Resistant Mechanical Seamless PipeNegotiableMOQ: 1 Ton

-

A335 Heat Exchanger Tubes P9 T9 & K11597 Uniform Thickness Corrosion Resistant Commercial Heat Exchanger TubesNegotiableMOQ: 1 Ton

-

A335 Boiler Pipe P12 T12 & K21590 Smooth Inner Wall High Temp Tolerant Thermal Power Boiler PipeNegotiableMOQ: 1 Ton

-

High Pressure A335 Alloy Pipe P11 T11 & K11562 Precision Dimension Wear Resistant Industrial Alloy PipeNegotiableMOQ: 1 Ton